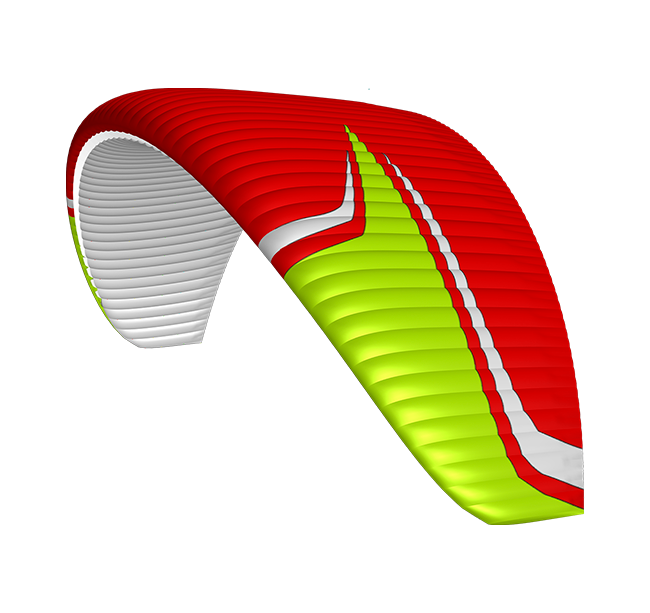

Kougar 3

The new design of the Konvers features a faster profile and a more solid, cleaner leading edge, resulting in a top speed of 80 km/h (±3).

Uniquely accessible with instant inflation and easy take off without requiring a lot of acceleration. A solid and compact PPG wing that is extremely stable with high passive safety in all phases of flight.

Cross-country

Its efficiency, good performance and the ability to reach its maximum speed, make it an ideal wing for long flights.

Competition

A high performance wing that is simultaneously very comfortable. This allows the pilot to focus completely on the perfect execution of their flight and achieve their competition goals.

Simple to reach maximum speed of 80 km/h (±3).

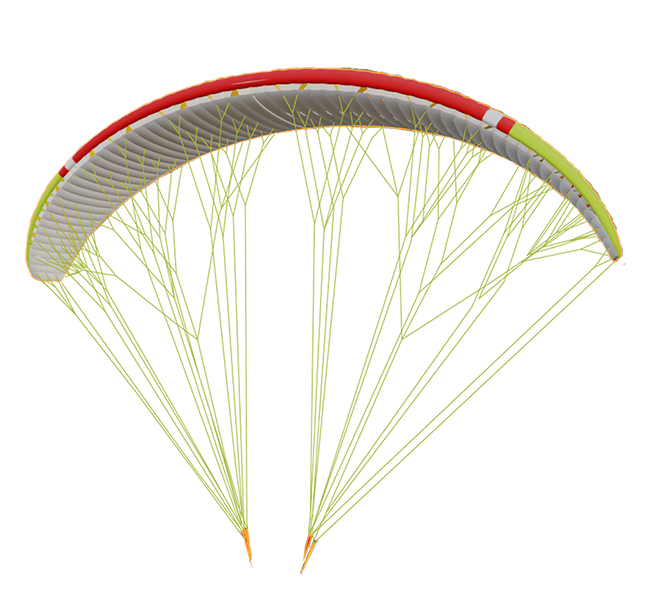

The trimmers and the speed-bar can be used together to reach the maximum speed, ensuring a maximum differential of 24 cm between the A and C risers.

Better performance with less fuel consumption.

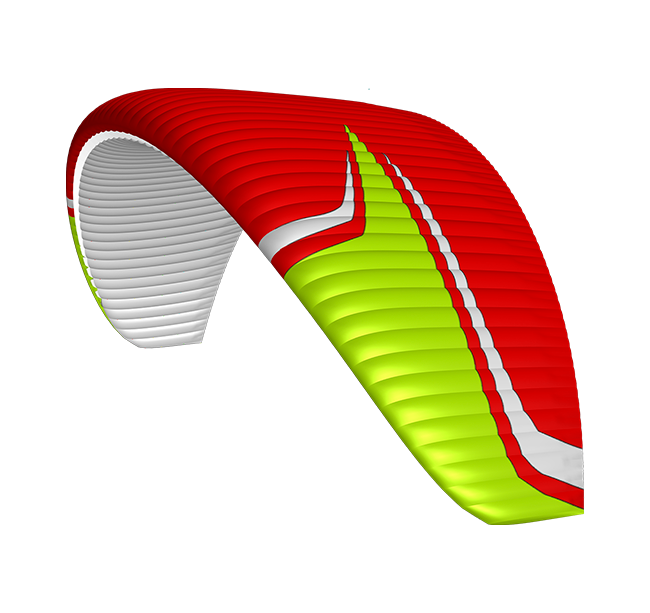

The new Kougar features a new and evolved reflex profile that makes the wing really solid across both its load and speed ranges.

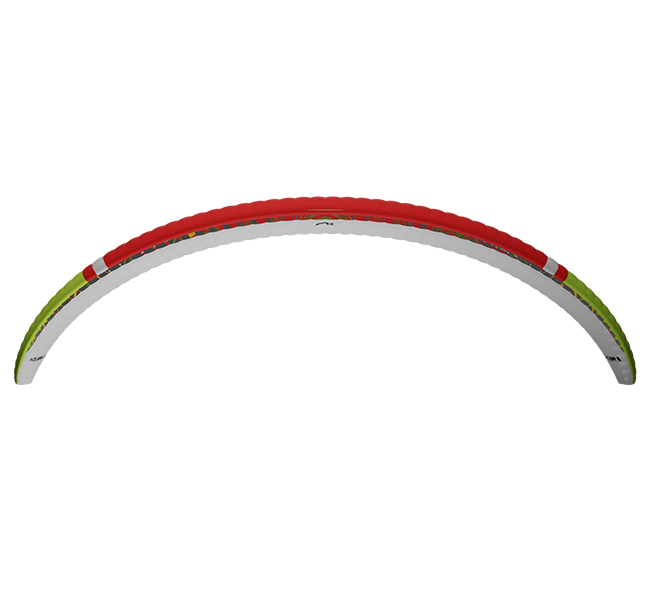

Its moderate aspect ratio (5.7) contributes to the pilot feeling safe and confident.

Requires less speed and engine power to take off.

Immediate launch thanks to its instant inflation where the glider is effortlessly placed over the pilot’s head.

Simple to reach maximum speed of 80 km/h (±3).

The trimmers and the speed-bar can be used together to reach the maximum speed, ensuring a maximum differential of 24 cm between the A and C risers.

Better performance with less fuel consumption.

The new Kougar features a new and evolved reflex profile that makes the wing really solid across both its load and speed ranges.

Its moderate aspect ratio (5.7) contributes to the pilot feeling safe and confident.

Requires less speed and engine power to take off.

Immediate launch thanks to its instant inflation where the glider is effortlessly placed over the pilot’s head.

3DL technology is an adjustment of the fabric at the leading edge of the wing to control the ballooning and the creases that are generated by the curvature in this area. The leading edge is then divided into sub-panels which are sewn into each of the cells at the front of the paraglider. As a result, the leading edge of the wing is perfectly tensioned, which benefits the wing in performance and durability.

A good comparison is a rugby ball. In order to produce its characteristic oval shape without creases, its cover is made of several panels – not of just one piece.

The application of this innovation, in conjunction with the 3DP, is key to converting the perfect shape from 2D to 3D.

The RAM Air Intake system is based on the inward orientation of the air inlets in the profile so that they allow an optimum internal pressure at all angles of attack.

The result? Having greater internal pressure means better buffering of turbulence, greater consistency of the profile shape across the speed range. Excellent handling at low speed is achieved by allowing the pilot to extend the braking limit, so there is a lower risk of collapse and consequently, greater control and stability.

This technology seeks to implement the best orientation of the cloth on each panel according to its location on the leading edge. If the cloth pattern is correctly aligned with the load axes, the cloth suffers less deformation flight after flight, so the leading edge maintains its shape better and remains stronger over time.

The design of our paraglider and paramotor wings has evolved a lot over the years, with a positive and specific focus on the leading edge.

Thanks to this technology and 3DL, a perfect modelling of the panels and an exact representation from 2D to 3D is achieved.

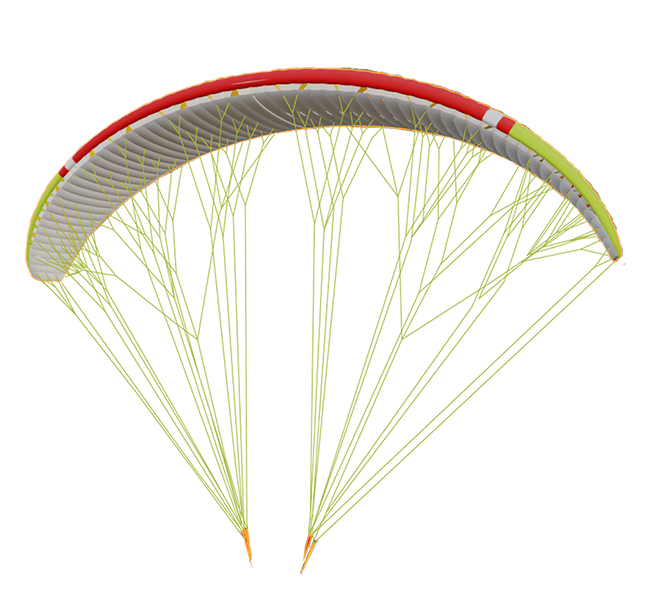

Nitinol is a combination of 50% nickel and 50% titanium. The incorporation of Nitinol rods in the profile increases the performance of the wing, especially in three areas:

- Compared to nylon rods, the weight of the wing is reduced by 13%.

- Nitinol has two essential characteristics: shape memory and enormous elasticity. As a result, the rods retain their optimum shape even after an ultra-compact or incorrect folding, so that the wing is not deformed. This will always be the case unless the radius at the point of curvature is less than 1 cm.

- The leading edge shape is much more rigid and uniform which results in a much more consistent and progressive inflation and therefore an easier take off. The profile is taut at all times, without creases, and fully optimised for all flight phases.

In addition, the rods have a plastic protector at their ends to prevent any damage to the fabric of the wing.

Nitinol is now featured in all our wings.

| 16 | 18 | 20 | 23 | 25 | 28 | |||

|---|---|---|---|---|---|---|---|---|

| CELLS | NUMBER | 64 | 64 | 64 | 64 | 64 | 64 | |

| ASPECT RATIO | FLAT | 5,75 | 5,75 | 5,75 | 5,75 | 5,75 | 5,75 | |

| PROJECTED | 4,52 | 4,52 | 4,52 | 4,52 | 4,52 | 4,52 | ||

| AREA | FLAT | m² | 16 | 18 | 20 | 22,5 | 25 | 28 |

| PROJECTED | m² | 13,90 | 15,65 | 17,38 | 19,55 | 21,73 | 24,34 | |

| SPAN | FLAT | m | 9,6 | 10,2 | 10,7 | 11,5 | 12 | 12,7 |

| CHORD | MAXIMUM | m | 2,06 | 2,18 | 2,30 | 2,44 | 2,57 | 2,72 |

| LINES | TOTAL | m | 238 | 253 | 267 | 285 | 300 | 319 |

| MAIN | 2+1/4/3/2 | 2+1/4/3/2 | 2+1/4/3/2 | 2+1/4/3/2 | 2+1/4/3/2 | 2+1/4/3/2 | ||

| RISERS | NUMBER | A+A’/B/C’+C/D | A+A’/B/C’+C/D | A+A’/B/C’+C/D | A+A’/B/C’+C/D | A+A’/B/C’+C/D | A+A’/B/C’+C/D | |

| SPEED-BAR | mm | 130 | 130 | 130 | 130 | 130 | 130 | |

| TRIMMERS | mm | 80 | 90 | 90 | 120 | 120 | 120 | |

| SPEED RANGE | CLOSED TRIM | km/h | 40 (± 2 km/h) | 40 (± 2 km/h) | 40 (± 2 km/h) | 40 (± 2 km/h) | 40 (± 2 km/h) | 40 (± 2 km/h) |

| OPEN TRIM | km/h | 60 (± 2 km/h) | 60 (± 2 km/h) | 60 (± 2 km/h) | 60 (± 2 km/h) | 60 (± 2 km/h) | 60 (± 2 km/h) | |

| TOP SPEED | km/h | 80 (± 2 km/h) | 80 (± 2 km/h) | 80 (± 2 km/h) | 80 (± 2 km/h) | 80 (± 2 km/h) | 80 (± 2 km/h) | |

| GLIDER WEIGHT | kg | 4,0 | 4,3 | 4,6 | 5,0 | 5,4 | 5,8 | |

| TOTAL WEIGHT IN FLIGHT | MIN-MAX | kg | 60-125 | 65-140 | 70-155 | 80-175 | 90-195 | 100-215 |

| IDENTIFICATION/CERTIFICATION | DGAC/EN 926-1 | DGAC/EN 926-1 | DGAC/EN 926-1 | DGAC/EN 926-1 | DGAC/EN 926-1 | DGAC/EN 926-1 |

The total weight of the wing may differ ±2% due to variations in the weight of the fabric supplied by the manufacturers.

Kougar 3

It contains an 8-digit code that, when entered in the MyNiviuk section, can be used for product registration, to carry out procedures and request maintenance.