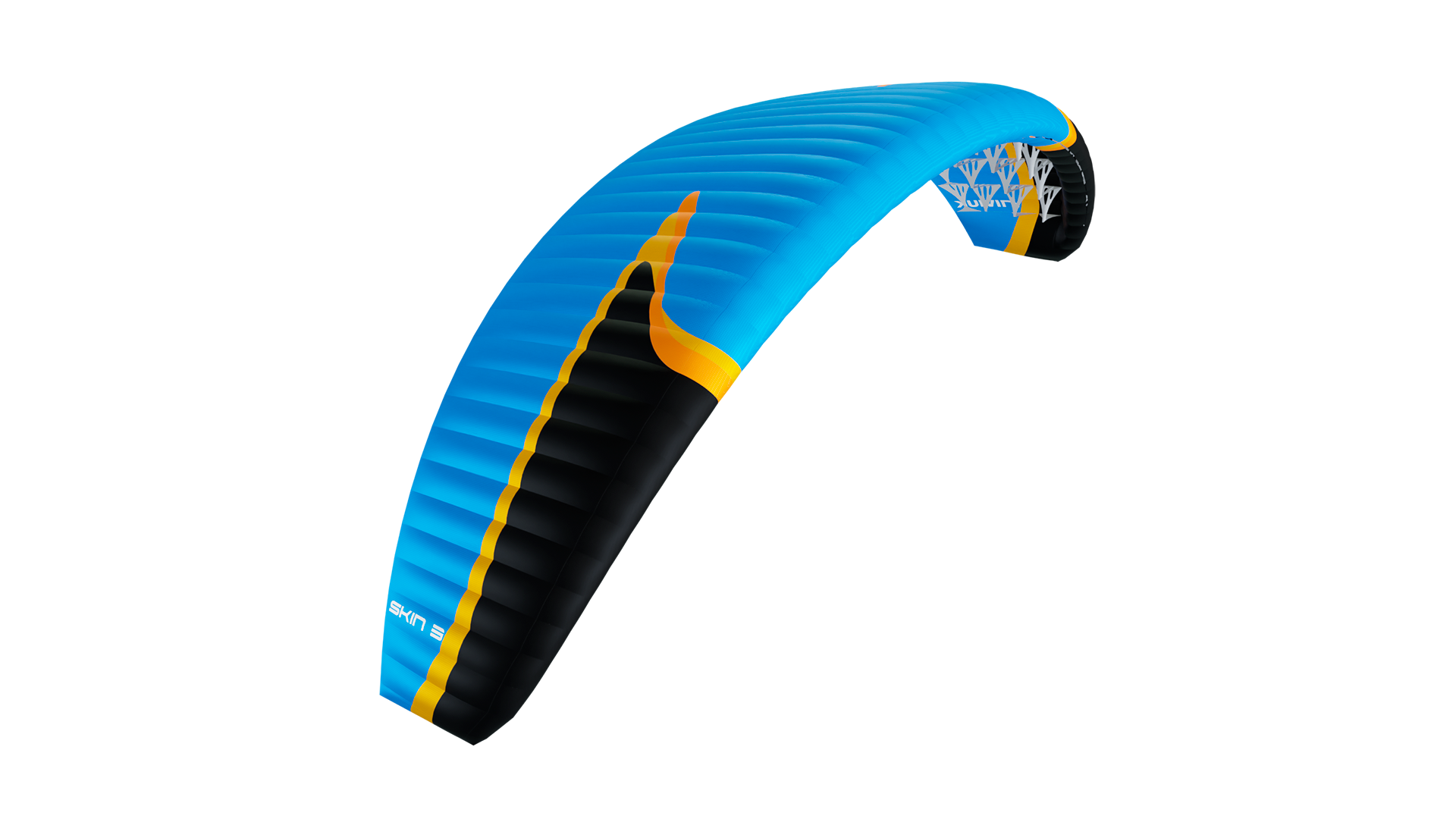

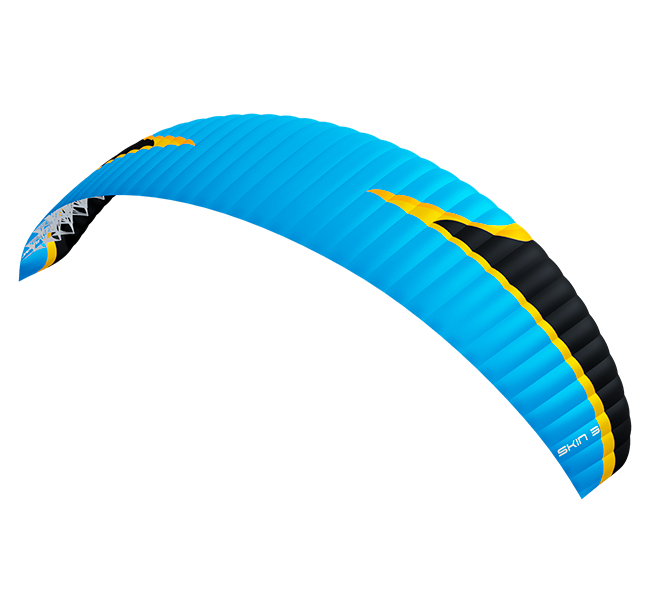

Skin 3

Much more efficient in turbulent conditions, headwind and for flying distance. Unlike other single-surface wings, its nature does not influence its flight behavior.

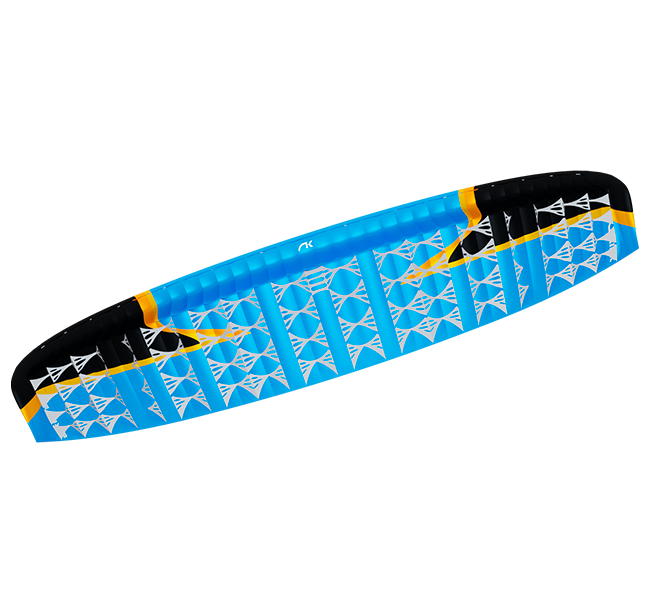

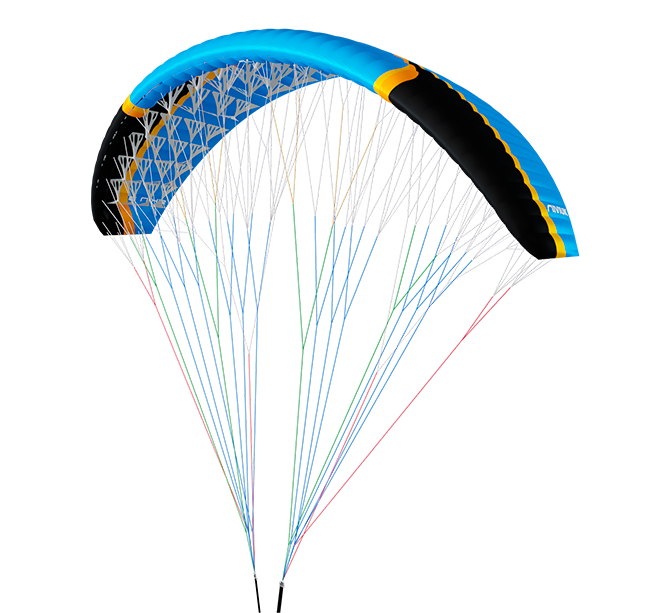

The wing’s revolutionary new reinforced structure makes it possible to greatly reduce the number of lines and together with the use of semi-light materials makes it light and also durable.

An EN B certified wing which is responsive, efficient and stable for greater flying comfort. More fun, more speed and a lot more accessible and simple to fly.

Progression

A pilot in the progression and learning phase will feel confident, thanks to the wing’s high stability and simple and intuitive handling. Safety and fun guaranteed.

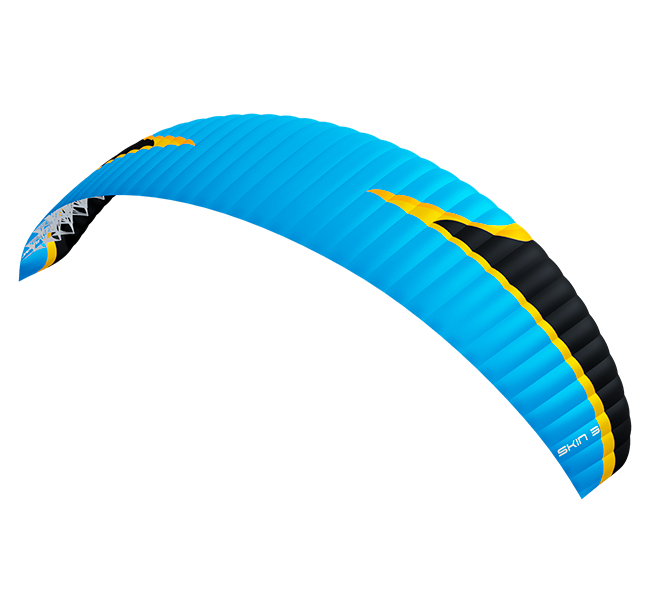

Hike & Fly

The perfect adventure companion for mountaineers looking for new challenges. It takes off anywhere, with unprecedented accessibility and high passive safety.

Vol-biv

Its improvement in glide, thermal performance and when facing adverse wind conditions permits safe distance flights like no other single-surface glider.

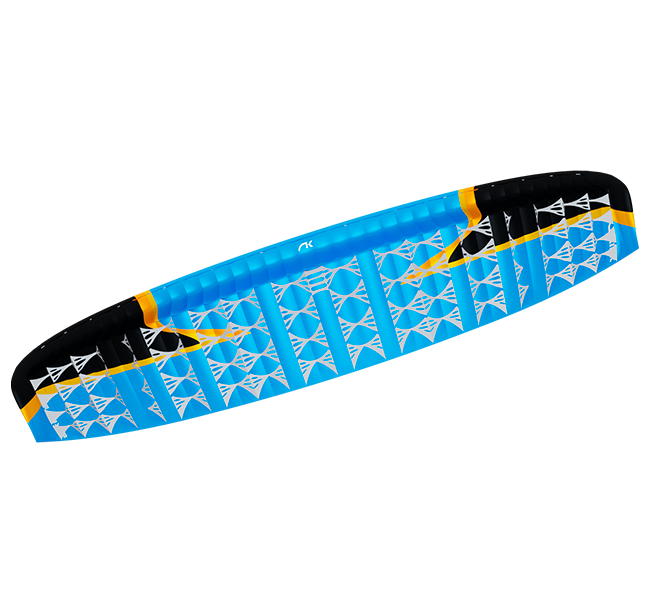

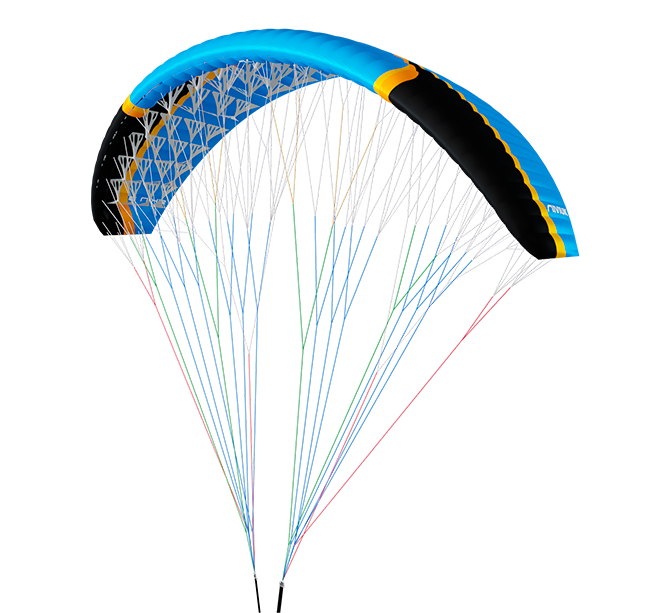

The redesign of its internal structure resulted in 44% fewer lines.

Using semi-light (Skin 3) and ultralight (Skin 3 P) materials ensures the wing is both light and compact.

Nitinol (TNT) rods are used in the wing profile instead of conventional nylon rods.

Excellent performance in thermals thanks to the combination of its new design with the latest Niviuk technologies.

Better glide and improved behavior in headwind and turbulent air.

Higher passive safety in the various phases of flight.

Excellent stability thanks to easy and accessible controls.

Steady and fun flying.

Easy to quickly recover in the case of any type of collapse.

The launch is easier thanks to the new self-inflating leading edge. The wing climbs above the pilot without any difficulty.

Increased brake travel for smoother and more precise landing.

The redesign of its internal structure resulted in 44% fewer lines.

Using semi-light (Skin 3) and ultralight (Skin 3 P) materials ensures the wing is both light and compact.

Nitinol (TNT) rods are used in the wing profile instead of conventional nylon rods.

Excellent performance in thermals thanks to the combination of its new design with the latest Niviuk technologies.

Better glide and improved behavior in headwind and turbulent air.

Higher passive safety in the various phases of flight.

Excellent stability thanks to easy and accessible controls.

Steady and fun flying.

Easy to quickly recover in the case of any type of collapse.

The launch is easier thanks to the new self-inflating leading edge. The wing climbs above the pilot without any difficulty.

Increased brake travel for smoother and more precise landing.

3DL technology is an adjustment of the fabric at the leading edge of the wing to control the ballooning and the creases that are generated by the curvature in this area. The leading edge is then divided into sub-panels which are sewn into each of the cells at the front of the paraglider. As a result, the leading edge of the wing is perfectly tensioned, which benefits the wing in performance and durability.

A good comparison is a rugby ball. In order to produce its characteristic oval shape without creases, its cover is made of several panels – not of just one piece.

The application of this innovation, in conjunction with the 3DP, is key to converting the perfect shape from 2D to 3D.

The RAM Air Intake system is based on the inward orientation of the air inlets in the profile so that they allow an optimum internal pressure at all angles of attack.

The result? Having greater internal pressure means better buffering of turbulence, greater consistency of the profile shape across the speed range. Excellent handling at low speed is achieved by allowing the pilot to extend the braking limit, so there is a lower risk of collapse and consequently, greater control and stability.

This technology seeks to implement the best orientation of the cloth on each panel according to its location on the leading edge. If the cloth pattern is correctly aligned with the load axes, the cloth suffers less deformation flight after flight, so the leading edge maintains its shape better and remains stronger over time.

The design of our paraglider and paramotor wings has evolved a lot over the years, with a positive and specific focus on the leading edge.

Thanks to this technology and 3DL, a perfect modelling of the panels and an exact representation from 2D to 3D is achieved.

Nitinol is a combination of 50% nickel and 50% titanium. The incorporation of Nitinol rods in the profile increases the performance of the wing, especially in three areas:

- Compared to nylon rods, the weight of the wing is reduced by 13%.

- Nitinol has two essential characteristics: shape memory and enormous elasticity. As a result, the rods retain their optimum shape even after an ultra-compact or incorrect folding, so that the wing is not deformed. This will always be the case unless the radius at the point of curvature is less than 1 cm.

- The leading edge shape is much more rigid and uniform which results in a much more consistent and progressive inflation and therefore an easier take off. The profile is taut at all times, without creases, and fully optimised for all flight phases.

In addition, the rods have a plastic protector at their ends to prevent any damage to the fabric of the wing.

Nitinol is now featured in all our wings.