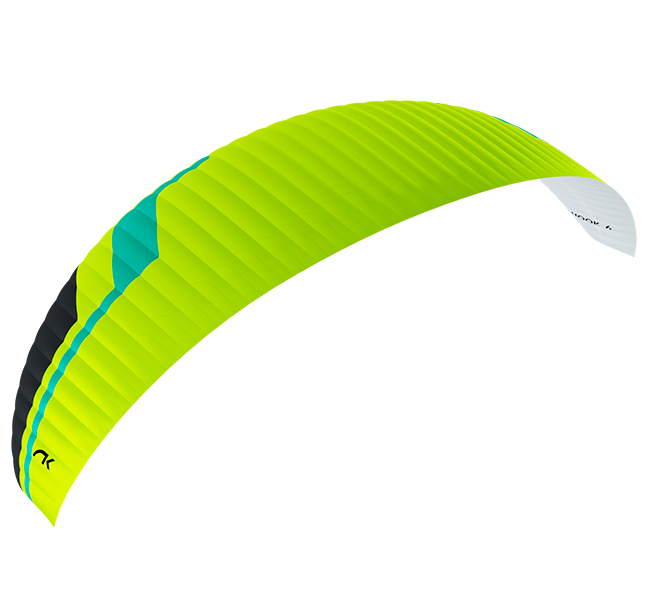

Hook 6

Progression

A very intuitive, stable and safe wing, it has greater features and performance than the previous model. Ideal for progressing, as well as taking the leap to new and different modes of flying. With optimised handling to enhance the pilot’s flying experience.

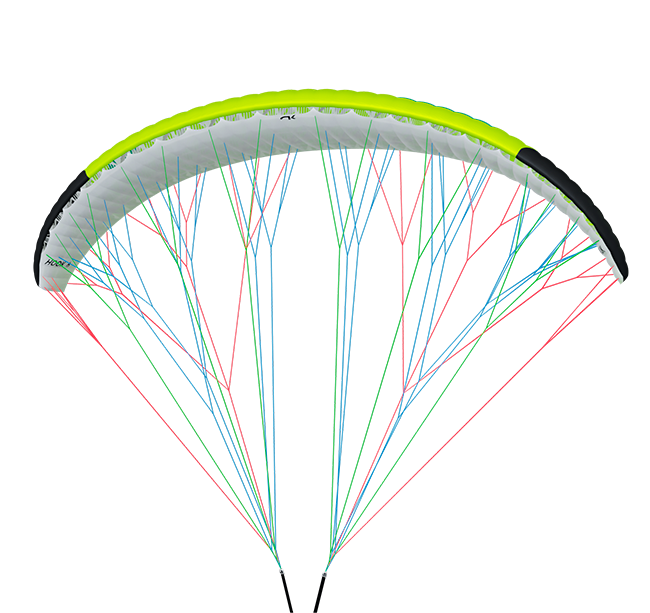

The Hook 6 features reinforced Kevlar risers which weigh less and are much stronger. The webbing has been reduced from 21 mm to 12 mm. Therefore, the drag has been subtly reduced.

The canopy is made of light and durable materials reducing the weight of the glider without compromising its durability.

The leading edge is made of Dokdo 40 gr/m2 and the rest of the canopy is made of Dokdo 36 gr/m2 (the wing weighs only 4.2 kg in size 22).

The Hook 6 features reinforced Kevlar risers which weigh less and are much stronger. The webbing has been reduced from 21 mm to 12 mm. Therefore, the drag has been subtly reduced.

The canopy is made of light and durable materials reducing the weight of the glider without compromising its durability.

The leading edge is made of Dokdo 40 gr/m2 and the rest of the canopy is made of Dokdo 36 gr/m2 (the wing weighs only 4.2 kg in size 22).

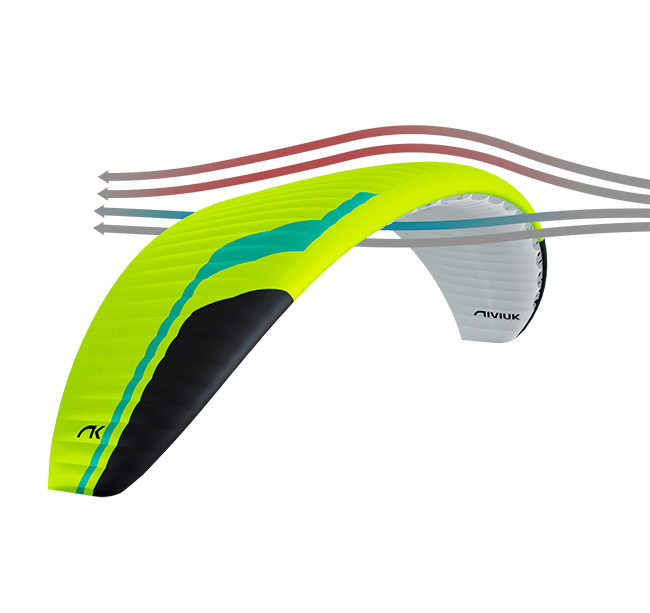

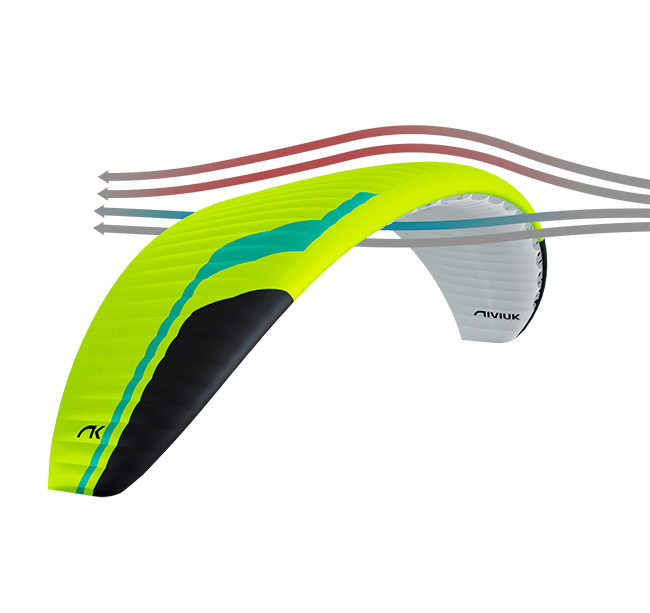

3DL technology is an adjustment of the fabric at the leading edge of the wing to control the ballooning and the creases that are generated by the curvature in this area. The leading edge is then divided into sub-panels which are sewn into each of the cells at the front of the paraglider. As a result, the leading edge of the wing is perfectly tensioned, which benefits the wing in performance and durability.

A good comparison is a rugby ball. In order to produce its characteristic oval shape without creases, its cover is made of several panels – not of just one piece.

The application of this innovation, in conjunction with the 3DP, is key to converting the perfect shape from 2D to 3D.

The RAM Air Intake system is based on the inward orientation of the air inlets in the profile so that they allow an optimum internal pressure at all angles of attack.

The result? Having greater internal pressure means better buffering of turbulence, greater consistency of the profile shape across the speed range. Excellent handling at low speed is achieved by allowing the pilot to extend the braking limit, so there is a lower risk of collapse and consequently, greater control and stability.

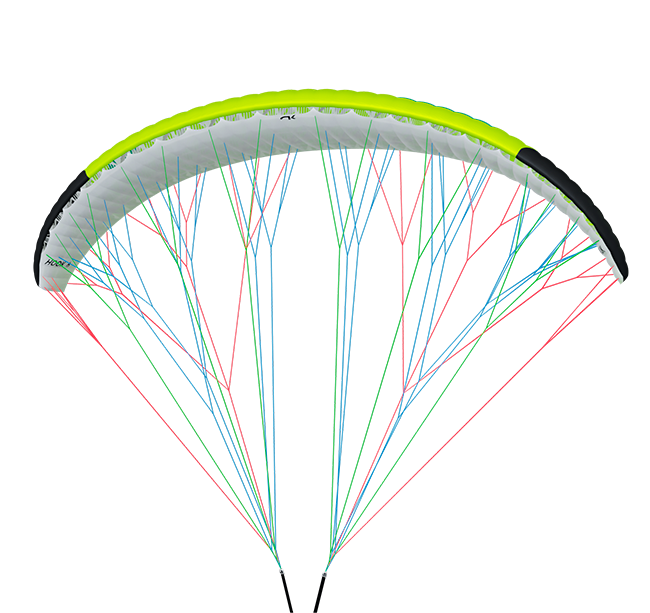

RSD (Radial Sliced Diagonal) technology is a reinvention of the wing’s internal structure. It incorporates independent and efficiently oriented diagonal ribs, which follow the direction of the cloth. This improves the strength, reduces weight and minimises deformation.

These days, in order to improve stress distribution and reduce the number of attachment points and lines, most wings have these diagonal ribs, which are connected from the attachment points to the adjacent profiles.

In conventional diagonal ribs, loading and unloading cycles away from the highest strength axis of the cloth result in a loss of shape, which reduces the cohesion of the wing and therefore aerodynamic efficiency.

This technology seeks to implement the best orientation of the cloth on each panel according to its location on the leading edge. If the cloth pattern is correctly aligned with the load axes, the cloth suffers less deformation flight after flight, so the leading edge maintains its shape better and remains stronger over time.

The design of our paraglider and paramotor wings has evolved a lot over the years, with a positive and specific focus on the leading edge.

Thanks to this technology and 3DL, a perfect modelling of the panels and an exact representation from 2D to 3D is achieved.

Nitinol is a combination of 50% nickel and 50% titanium. The incorporation of Nitinol rods in the profile increases the performance of the wing, especially in three areas:

- Compared to nylon rods, the weight of the wing is reduced by 13%.

- Nitinol has two essential characteristics: shape memory and enormous elasticity. As a result, the rods retain their optimum shape even after an ultra-compact or incorrect folding, so that the wing is not deformed. This will always be the case unless the radius at the point of curvature is less than 1 cm.

- The leading edge shape is much more rigid and uniform which results in a much more consistent and progressive inflation and therefore an easier take off. The profile is taut at all times, without creases, and fully optimised for all flight phases.

In addition, the rods have a plastic protector at their ends to prevent any damage to the fabric of the wing.

Nitinol is now featured in all our wings.

A new design with a strategic distribution of the slots improves the load distribution inside the glider while making it lighter.

The use of new mini-ribs in the trailing edge decreases drag and improves the aerodynamic shape of the wing. DRS technology has been optimised: the cutting of the trailing edge permits full intergradation of the mini-ribs without the use of external stitching.

Precision profile manufacture achieves a much cleaner finish to avoid creases and minimise aerodynamic drag. This harmonises stability, speed and performance.

For increased strength and durability, the Hook 6 P risers feature with a small pulley with ball bearings (developed together with Harken) at the brake connection.

As in our other wings, Nitinol rods are used to maintain the optimal shape of the canopy, even after ultra-compact folding.

Its leading edge has a structured design (SLE technology), an extra seam on the span axis (3DL technology) and ideal tensioning without deformations based on the 3DP technology. The use of these technologies ensures the durability of the glider.

| 20 | 22 | 24 | 26 | 28 | 31 | |||

|---|---|---|---|---|---|---|---|---|

| CELLS | NUMBER | 47 | 47 | 47 | 47 | 47 | 47 | |

| ASPECT RATIO | FLAT | 5,3 | 5,3 | 5,3 | 5,3 | 5,3 | 5,3 | |

| PROJECTED | 4 | 4 | 4 | 4 | 4 | 4 | ||

| AREA | FLAT | m² | 20 | 22 | 24 | 26 | 28 | 31 |

| PROJECTED | m² | 17,15 | 18,87 | 20,59 | 22,30 | 24,02 | 26,59 | |

| SPAN | FLAT | m | 10,30 | 10,80 | 11,28 | 11,74 | 12,18 | 12,82 |

| CHORD | MAXIMUM | m | 2,43 | 2,55 | 2,66 | 2,77 | 2,87 | 3,02 |

| LINES | TOTAL | m | 205 | 215 | 226 | 235 | 244 | 258 |

| MAIN | 2-1/3/2 | 2-1/3/2 | 2-1/3/2 | 2-1/3/2 | 2-1/3/2 | 2-1/3/2 | ||

| RISERS | NUMBER | A-A’/B/C | A-A’/B/C | A-A’/B/C | A-A’/B/C | A-A’/B/C | A-A’/B/C | |

| SPEED-BAR | mm | 120 | 145 | 145 | 145 | 145 | 145 | |

| GLIDER WEIGHT | kg | 3,9 | 4,2 | 4,5 | 4,8 | 5,1 | 5,5 | |

| TOTAL WEIGHT IN FLIGHT | MIN-MAX | kg | 55-70 | 60-80 | 70-92 | 80-105 | 95-120 | 110-135 |

| CERTIFICATION |

EN/LTF B

|

EN/LTF B

|

EN/LTF B

|

EN/LTF B

|

EN/LTF B

|

EN/LTF B

|

The total weight of the wing may differ ±2% due to variations in the weight of the fabric supplied by the manufacturers.

Hook 6

It contains an 8-digit code that, when entered in the MyNiviuk section, can be used for product registration, to carry out procedures and request maintenance.