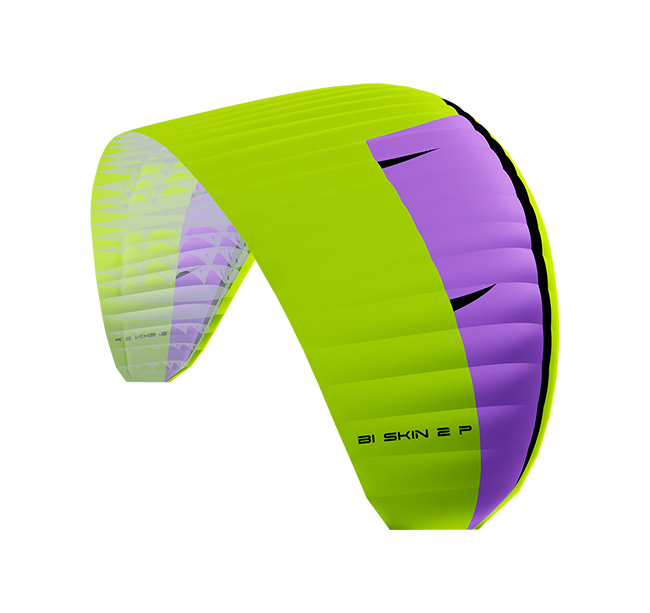

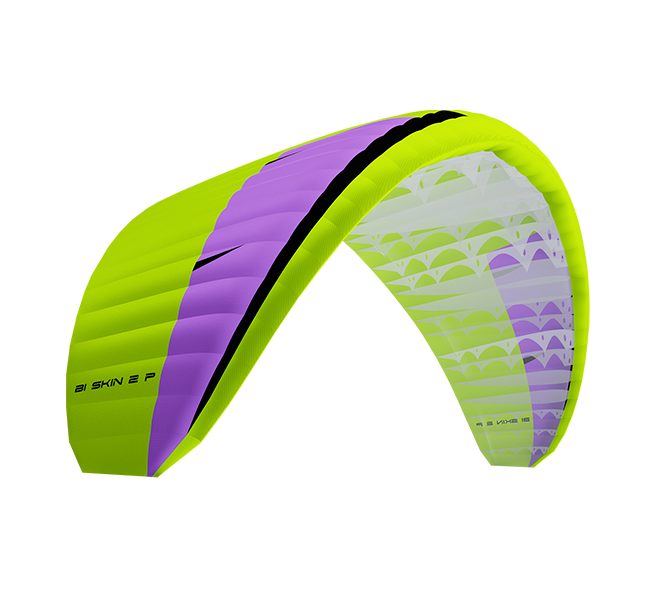

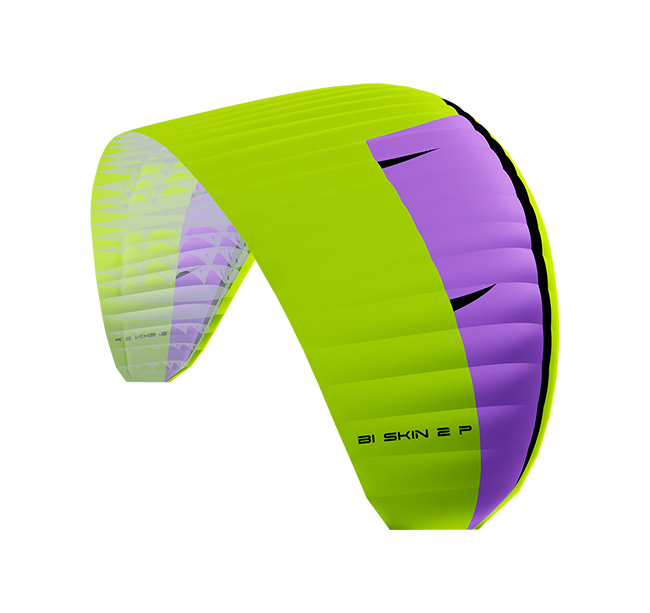

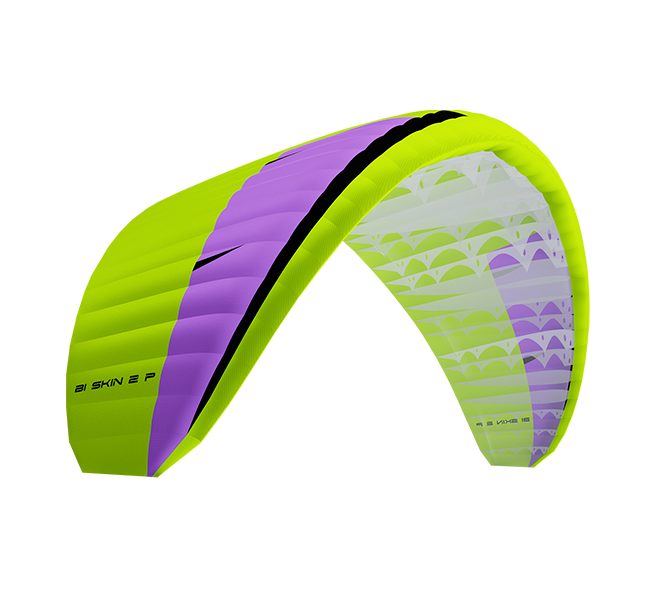

Bi Skin 2 P

Weighing only 3.3 kg and with an extremely small packing volume, this single-surface wing has the capacity to carry up to 190 kg and to take you on incomparable adventures.

Joint take offs, incredible flights and gentle but absolutely controlled landings. With the Bi Skin 2 P, innovation is not just taking a step forward, but exploring new directions. Discover the wing that marks a milestone in the world of paragliding.

From 3.3 kg.

Hike and fly, tandem and vol-biv

Share your mountain and alpine adventures with a wing that will allow you to take off in countless places, with unprecedented user-friendliness and a high level passive safety.

Extremely light weight and small volume (3.3 kg) due to the use of semi-light material on the upper surface, 12 mm thin risers, unsheathed Aramid lines and an IKS 1000 attachment system between line and riser.

An instant inflation that translates into an easy and agile take off thanks to the absence of an undersurface.

Precise and very safe landing, thanks to the excellent trim system that allows an exceptional speed retention for a smoother roundout.

A canopy designed with consideration of better tension and compactness of the wing, thus avoiding vibrations.

The IKS (Interlock System) attachment system ensures maximum safety for both pilot and passenger.

A low and stable aspect ratio of 5.5 (typical of the EN B class).

Use of semi-light and highly durable materials (Porcher 32 g, Porcher 38 g, Aramid and Kevlar webbing).

Nitinol rods have been used in the profile to increase its robustness, and give it more uniformity and flexibility.

Extremely light weight and small volume (3.3 kg) due to the use of semi-light material on the upper surface, 12 mm thin risers, unsheathed Aramid lines and an IKS 1000 attachment system between line and riser.

An instant inflation that translates into an easy and agile take off thanks to the absence of an undersurface.

Precise and very safe landing, thanks to the excellent trim system that allows an exceptional speed retention for a smoother roundout.

A canopy designed with consideration of better tension and compactness of the wing, thus avoiding vibrations.

The IKS (Interlock System) attachment system ensures maximum safety for both pilot and passenger.

A low and stable aspect ratio of 5.5 (typical of the EN B class).

Use of semi-light and highly durable materials (Porcher 32 g, Porcher 38 g, Aramid and Kevlar webbing).

Nitinol rods have been used in the profile to increase its robustness, and give it more uniformity and flexibility.

| 31 | |||

|---|---|---|---|

| CELLS | NUMBER | 39 | |

| ASPECT RATIO | FLAT | 5,5 | |

| PROJECTED | 4,12 | ||

| AREA | FLAT | m² | 31 |

| PROJECTED | m² | 26,17 | |

| SPAN | FLAT | m | 13,06 |

| CHORD | MAXIMUM | m | 2,94 |

| LINES | TOTAL | m | 522 |

| MAIN | 3/3/4/3 | ||

| RISERS | NUMBER | A/B/C/D | |

| TRIMMERS | mm | 60 | |

| GLIDER WEIGHT | kg | 3,3 | |

| TOTAL WEIGHT IN FLIGHT | MIN-MAX | kg | 130-190 |

| CERTIFICATION |

EN/LTF B

|

The total weight of the wing may differ ±2% due to variations in the weight of the fabric supplied by the manufacturers.

Bi Skin 2 P

It contains an 8-digit code that, when entered in the MyNiviuk section, can be used for product registration, to carry out procedures and request maintenance.